The development of centrifuges has been nearly two hundred years.The first centrifuge was invented in Germany in 1836.

The Earliest Use of Centrifugal Force in Ancient China

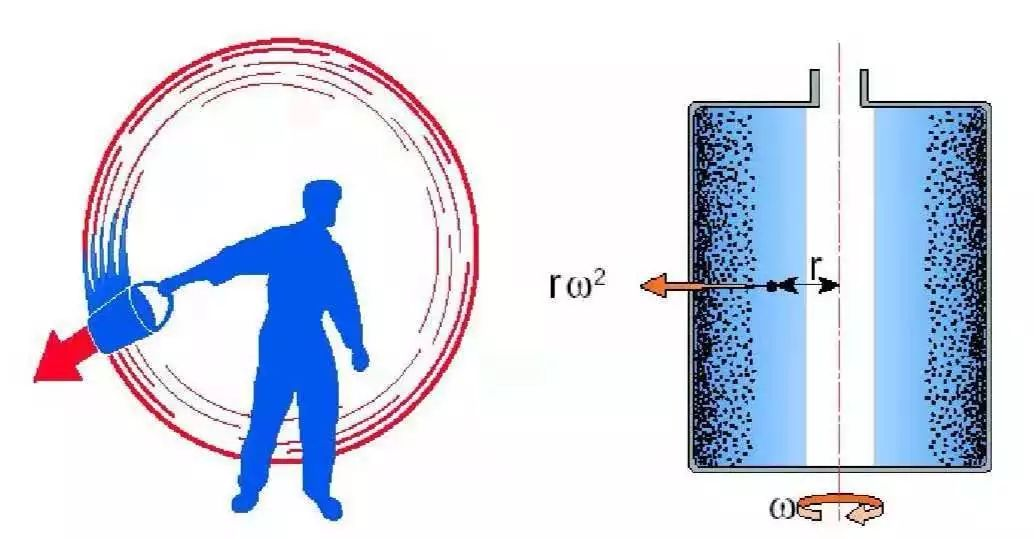

The ancient Chinese people used one end of a rope to tie a clay pot, hold the other end of the rope, and whirl the pot to produce centrifugal force to squeeze out the honey in the pot.

World Modern Centrifuges Development History

Modern centrifuges originated in the 18th century ,a British military engineers invented a rotating arm device for determining resistance.

In the 19th century, a pair of European brothers wanted to separate cream from milk and proposed a dairy product centrifuge idea. The brothers designed and improved their products and invented the first milk fat centrifuge that can separate cows and cows from milk. This is also the world’s first centrifuge for industrial production.

Later, a three-foot centrifuge for textile dehydration and an overhead centrifuge for separating crystalline sugar in sugar factories were developed. It was not until the 1930s that an automatic centrifuge with continuous operation was developed.

In 1950, in Switzerland, the centrifuge was once again improved in performance. At this time, the centrifuge can already be directly driven by a variable frequency motor.

Modern Centrifuges Development History in China

The development of centrifugal technology in the world has greatly promoted the development of Chinese medical technology. The following pictures of centrifuges reflect the development and progress of Chinese medical laboratory in the past 40 years.

As can be seen from the photos above, after nearly 40 years of development, modern centrifuges in China have improved the structure and centrifugation methods to increase the speed of the centrifuge from tens of revolutions to hundreds of thousands; the life of the drive system has been increased from 1 billion revolutions to 20 billion revolutions; The appearance develops towards beautiful, practical and miniaturized.

KETHINK Lab Centrifuge New Technology

Based on more than 20 years of laboratory centrifuge research and development technology, KETHINK has adapted to the needs of modern industries and has developed more professional use laboratory centrifuges of various styles and centrifuges suitable for specific experimental procedures for customers to choose.

We adopted the following new technologies to update our centrifuges and make it better in performance and more convenient to use.

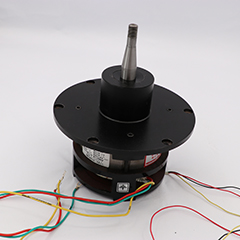

- Brushless Motor Direct Drive

The centrifuge is rotated at a high speed by a motor with a rotor. In the past, the motor was a DC motor with carbon brushes. When the centrifuge was running, the carbon brushes were worn out, which caused sparks, noise and even vibration. The carbon brushes should be replaced regularly. What’s more serious is the pollution of carbon dust caused by the wear of carbon brushes, which not only pollutes the centrifuge, but also pollutes the surrounding environment. This kind of pollution is not suitable for the medical & biology industry.

So we replaced this motor with a brushless motor, which is environmentally friendly, maintenance-free, pollution-free. It makes a centrifuge with a longer service life.

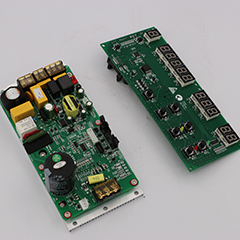

- Digital Display Technology

The earliest centrifuges used knobs to select operating parameters (such as rotation speed, temperature, and time, etc.), and used dial pointers to display data. The disadvantage is that the reading value of the selected parameters and data is much interfered by the operator and the reading person, and the control accuracy is poor. Have to repeat the setting routine before every operation.

KETHINK updated the centrifuge display screen to LED/LCD digital display, programmable operation controlled by computer. All parameters needed for centrifuge operation (such as speed, temperature, time, acceleration and deceleration rate files, etc.) are input using the panel keys and displayed in numbers, so the error between the selected operating parameters and the read number is very small. At the same time, because it is a programmable operation, a group of operating parameters can be coded into numbers, which can be accessed and used.

- Temperature Cooling Technology

When the rotor rotates at a high speed, air friction generates heat, the temperature of the rotor will rise, and the temperature of the sample in the test tube will also rise. Because biological samples are sensitive to temperature. It is generally required that the temperature be maintained at 4°C during the centrifugal experiment.

Without computer-controlled intelligent technology, it is impossible to achieve an accuracy of ±1°C. Therefore, a refrigerator is used to cool the centrifugal cavity to achieve the purpose of cooling the rotor and cooling the temperature of the sample. However, it is extremely difficult to measure the actual temperature of the rotating rotor. So temperature sensors are installed at the bottom of the centrifugal cavity closer to the rotor to indirectly measure the temperature of the rotor.

DIY Centrifuge

A professional level lab centrifuge is a necessary equipment for many medical & biology applications,but it is rather expensive & large for some people.Even though some are as low cost at around $150 with rotor. It seems to be beyond their budgets. Some people might be wondering how to make a simple centrifuge with lower costs.

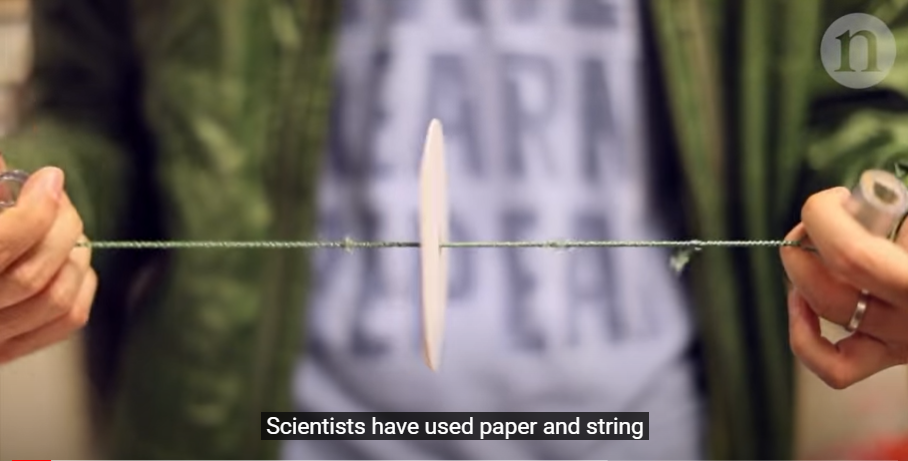

The answer is yes. Researchers from Stanford University used paper to develop an extremely cheap centrifuge. This technology can easily and quickly detect malaria and other diseases in developing countries. This device, called “Paperfuge” (Paperfuge), costs only US$0.2 (about RMB 1.38). The required materials can be found even in remote areas, and it does not require electricity. For those It is the best choice for doctors in remote areas. This “centrifuge” can be made with simple materials such as paper and rope, and is driven by manpower. Many people not only thinking of making their own centrifuge, but they make it real. Let us take a look at some of these below.

- Paper and string: the DIY centrifuge

- D’Art of Science:how to make a centrifuge machine?

There is another DIY centrifuge project in school with slight difference from the above video uses steel wire ,pilers ,cardboard,double sided foam tape,etc to make a centrifuge.

- Homemade Centrifuge

The following video shows you another low cost DIY centrifuge by using a brushless DC motor, a 3d printed 9g rotor stainless jar. The motor is mounted with some machine screws and a chunk of wood and glued to the bottom of a canister jar. The motor is driven by a common motor ESC and PWM controller and supplied with a 12v 5a supply. The simple centrifuge can spin to roughly 42,717g based on the tachometer and radius of rotor.