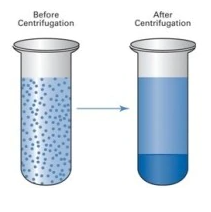

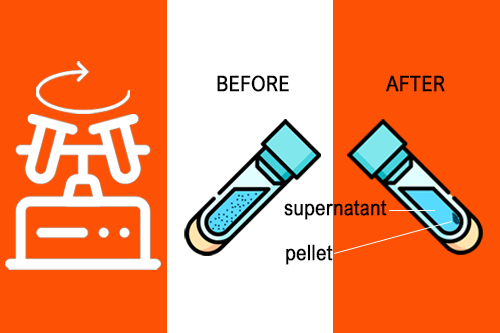

Centrifugation is a technique for separating particles from a solution based on particle size, shape, density, media viscosity, and rotor speed. Particles are suspended in liquid medium and placed in centrifuge tubes. The tube is then placed in the rotor and rotated at the specified speed. Separation by sedimentation can be done naturally under the influence of Earth’s gravity, however, it takes a long time. Centrifuges make this natural process faster.

What is pellet in centrifugation ?

Best centrifuges work on the principle of sedimentation: under the influence of gravity (g-force), substances separate according to density. Different types of separation are known, including isopycnic, ultrafiltration, density gradient, phase separation and granulation.

Typically, centrifugation applications specify the forcesof acceleration applied to the sample, rather than specifying a specific rotational speed, such as revolutions per minute. Acceleration is usually given in terms of gravity [× g] (or a multiple of xg or g force), which is the standard value of acceleration due to gravity on the Earth’s surface (9.81 m/s 2 ). The distinction between rpm and rcf is important because two rotors of different diameters running at the same rotational speed (rpm) result in different accelerations (rcf).

What factors affect centrifugation:

- Density of samples and solutions

- temperature/viscosity

- particle displacement distance

- spinning speed

There are two types of centrifuge procedures; one is preparative, which aims to separate specific particles, and the other is analytical, which involves measuring the physical properties of settled particles.

Two forces counteract the centrifugal force acting on the suspended particles

- Buoyant force: force with which the particles must displace the liquid media into which they sediment.

- Frictional force: force generated by the particles as they migrate through the solution.

Particles move away from the axis of rotation in a centrifugal field only when the centrifugal force exceeds the counteracting buoyant and frictional forces resulting in sedimentation of the particles at a constant rate.

Relative Centrifuge Force (RCF) expressed in xg (multiple of earth gravitational force)

RFC = 1,118 x R x (rpm /1000)²

R is radius in cm

rpm : Speed in Revolutions per minute

- As a result, for the same speed, a radius 20% bigger gives a number of xg 20% higher.

How to convert between multiplying gravity (×g) and centrifuge rotor speed (RPM)?

Certain procedures require precise centrifugation conditions, which must be specified in relative centrifugal force (RCF), expressed in units of gravity (multiplied by gravity or × g). Many microcentrifuges only have a speed setting (revolutions per minute, RPM) and no relative centrifugal force. Therefore, a conversion formula is required to ensure that the appropriate settings are used in the experiment. The relationship between RPM and RCF is as follows:

g = (1.118 × 10-5) x R x S²

where g is the relative centrifugal force, R is the radius of the rotor in centimeters, and S is the speed of the centrifuge in revolutions per minute. RCF values (in gravity (× g)) for common microcentrifuge rotor radii are shown in the conversion table below. For example, centrifuging a sample at 5,000 RPM in a microcentrifuge with a 7 cm radius rotor will result in a centrifugal force of 1,957 × g.

In routine sample processing procedures involving benchtop microcentrifuges, centrifugation speed and time are usually not critical factors. In general, it does not matter if the speed is faster or if the time is longer than necessary as long as the speed and time are sufficient to ensure that the cells, debris or resin are efficiently pelleted. For this reason, many protocols do not specify the specific centrifugal force to be applied, but instead indicate some general guidelines such as “centrifuge at high speed for 1 minute”.

Example of Conversion Table

| Speed (RPM) | Rotor Radius (from center of rotor to sample) in centimeters |

| 4500 | 906 | 1132 | 1358 | 1585 | 1811 | 2038 | 2264 | 2490 | 2717 | 2943 | 3170 | 3396 |

| 5000 | 1118 | 1398 | 1677 | 1957 | 2236 | 2516 | 2795 | 3075 | 3354 | 3634 | 3913 | 4193 |

| 5500 | 1353 | 1691 | 2029 | 2367 | 2706 | 3044 | 3382 | 3720 | 4058 | 4397 | 4735 | 5073 |

| 6000 | 1610 | 2012 | 2415 | 2817 | 3220 | 3622 | 4025 | 4427 | 4830 | 5232 | 5635 | 6037 |

| 6500 | 1889 | 2362 | 2834 | 3306 | 3779 | 4251 | 4724 | 5196 | 5668 | 6141 | 6613 | 7085 |

| 7000 | 2191 | 2739 | 3287 | 3835 | 4383 | 4930 | 5478 | 6026 | 6574 | 7122 | 7669 | 8217 |

| 7500 | 2516 | 3144 | 3773 | 4402 | 5031 | 5660 | 6289 | 6918 | 7547 | 8175 | 8804 | 9433 |

| 8000 | 2862 | 3578 | 4293 | 5009 | 5724 | 6440 | 7155 | 7871 | 8586 | 9302 | 10017 | 10733 |

| 8500 | 3231 | 4039 | 4847 | 5654 | 6462 | 7270 | 8078 | 8885 | 9693 | 10501 | 11309 | 12116 |

| 9000 | 3622 | 4528 | 5433 | 6339 | 7245 | 8150 | 9056 | 9961 | 10867 | 11773 | 12678 | 13584 |

| 9500 | 4036 | 5045 | 6054 | 7063 | 8072 | 9081 | 10090 | 11099 | 12108 | 13117 | 14126 | 15135 |

| 10000 | 4472 | 5590 | 6708 | 7826 | 8944 | 10062 | 11180 | 12298 | 13416 | 14534 | 15652 | 16770 |